The Science Behind Acoustic Enclosures for Industrial Equipment

Noisy factory floors pose real risks to worker safety, hinder communication, and erode productivity. A recent study in industrial settings found that workers exposed to noise levels averaging around 78 dB(A) showed measurable declines in job performance, despite levels remaining within permissible limits.

Reliance on personal protective equipment alone provides only partial relief. Earplugs and other PPE are often uncomfortable, may reduce the ability to hear important verbal cues, and depend on proper use, factors that frequently undermine their effectiveness.

The smarter solution is to tackle noise at its source. Acoustic enclosures surround the factory equipment, turning down the volume before it reaches the worker, while preserving communication and workflow.

Basic Principles of Sound Control in Industrial Enclosures

Industrial noise typically falls into several distinct categories, each requiring a different acoustic strategy:

- Airborne noise travels through the air, think the whir of an engine, the roar of fans, or the clang of tool presses. It includes the movement of liquids or gases in pipes, such as hissing or gurgling sounds from high-pressure lines.

- Structure-borne noise occurs when machinery vibrations are transmitted through solid materials, such as floors or walls, which then radiate as sound elsewhere. Imagine a press vibrating through the floor into adjacent workspaces.

- Elasticity noise arises from materials under mechanical stress, such as metal expanding or contracting during manufacturing, causing sharp snapping or humming sounds.

These noise types can occur continuously, intermittently, or impulsively, depending on the equipment’s operation cycle.

Fundamental Soundproofing Concepts

Proper sound control relies on three basic strategies: mass, absorption, and decoupling.

Absorption tackles echoes and reverberation inside a space. This method utilises porous materials such as acoustic foam, mineral wool, or bonded cotton, which capture sound energy and convert it to low-grade heat. If you picture a room with hard surfaces, sound bounces around, creating a noisy, reflective environment. By lining it with absorptive materials, you reduce those reflections and improve clarity. This strategy is especially useful within enclosures, where reducing reverberation enhances sound control.

Mass law teaches us that denser materials block sound more effectively. For instance, a heavy steel panel will attenuate noise much better than a thin sheet metal one. Doubling the mass of a barrier yields approximately a 6 dB improvement in sound transmission loss, though the gains taper off with each additional layer.

Decoupling addresses structure-borne noise. When machinery vibrates, that vibration travels through solid structures. Decoupling breaks those physical pathways using techniques like mounting machines on vibration isolation pads or using isolation clips in walls. It is like removing the bridge that transmits shaking to the rest of the building; without contact, the vibration cannot travel.

Here is how they complement each other:

- A barrier stops airborne noise from escaping.

- Absorption reduces sound build-up inside the enclosure.

- Decoupling prevents structure-borne vibration from radiating noise through the building structure.

How Acoustic Enclosures Work: Key Components

Acoustic enclosures come in three main styles, chosen based on operational needs and noise control goals:

- Full enclosures surround the machinery, isolating it from all sides. They offer maximum noise reduction, often achieving upwards of 20 dB attenuation while still allowing visibility, access, and ventilation.

- Partial enclosures cover only part of the machine or block the most significant noise pathways. This approach reduces noise effectively with less material and cost.

- Integrated enclosures blend acoustic panels into existing structures or housings. They do not stand alone but reduce noise by combining with frames or equipment casings.

Materials and Construction

Acoustic enclosure performance hinges on the materials used and how they are assembled. One key solution is the use of composite panels. These consist of both a sound-blocking layer and an absorptive layer, enabling them to reduce the amount of noise that escapes while also dampening internal reflections.

A standout example of effective sound blocking and absorption in industrial settings is DECIBEL’s PZP™ metal perforated panels. These panels blend a perforated steel outer layer with a dense core of mineral felt and glass veil that traps and diffuses sound.

PZP panels deliver a dual benefit: they create a robust acoustic barrier and function as internal absorbers, all in a weather-resistant, durable system. These panels are available in customised dimensions, meet fire safety standards, and achieve a sound reduction even at moderate thickness.

Along with composite panels, acoustic lining plays a vital role in reducing internal sound. Materials like acoustic foams and mineral wool are applied inside the enclosure to absorb reverberation and prevent echoes from building up. These absorptive materials convert sound energy into heat, helping bring clarity to the internal acoustic environment.

Equally important are seals and joints. In an industrial enclosure, any small gap or joint can become a path for noise leakage. This is why tight-fitting gaskets and well-designed joints are essential to ensuring airtight containment. Gaskets are not only vital for acoustic integrity, but they also contribute to controlling vibration and improving overall enclosure performance.

Ventilation and Access Considerations

Acoustic performance must be balanced with the practical needs of machinery operation. Enclosures are usually customised with:

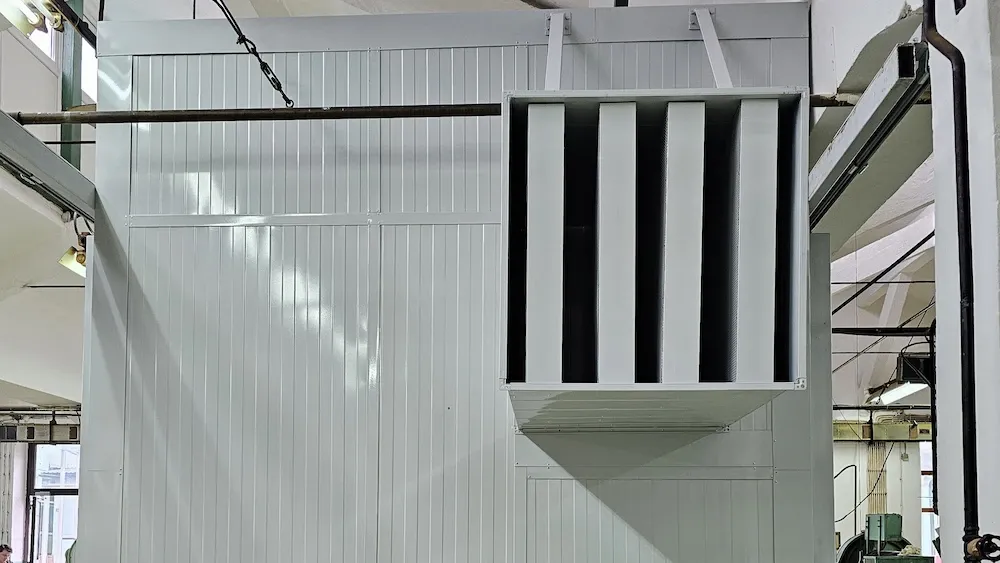

- Silenced ventilation systems, such as acoustic louvres or duct attenuators, allow air circulation while locking down sound paths.

- Access features like hinged or sliding doors, removable panels, and observation windows, all fitted with acoustic seals to preserve noise containment.

These components work together to create an effective acoustic enclosure. Full coverage shields noise at its source, composite materials enhance sound attenuation, and airflow and access remain operational, all while maintaining compliance and performance.

The Impact of Acoustic Enclosures in Industry

Well-engineered acoustic enclosures deliver concrete improvements in noise levels, helping create safer and more focused working environments. For instance, one study measured the effect of placing a noise-stopping enclosure around a roll former shear and found that the noise at the operator’s position decreased by 4 to 5 dB(A).

While that change may seem modest, a 4-5 dB reduction is noticeable to the human ear and can mark the difference between marginal and substantial noise comfort on the factory floor.

Health, Safety, and Compliance

Putting acoustic enclosures in place supports worker well-being and regulatory compliance. Lower noise exposure reduces the risk of noise-induced hearing loss, alleviates fatigue, and diminishes miscommunication that can lead to accidents.

As noise levels fall within safer thresholds, enclosures help meet standards set by agencies such as OSHA and NIOSH. That means fewer injury risks, improved clarity in alert systems, and more consistent, productive operations.

Business Benefits, Productivity and ROI

Acoustic enclosures bring significant business value beyond simply reducing noise. In quieter industrial environments, workers can focus more easily and experience less mental fatigue. Even moderate noise increases, such as 10 dB, can impair productivity by approximately 5%, according to studies on cognitive performance and workplace distraction.

Here are some of the most tangible benefits:

- Enhanced focus and fewer mistakes resulting in improved task accuracy

- Reduced reliance on personal protective equipment, which can hinder communication and comfort

- Decreased time off, as lower noise stress supports worker well-being

- Improved compliance with noise regulations, avoiding potential fines and supporting safety culture

These outcomes deliver a clear return on investment. Acoustic enclosures return value through increased output quality, lower equipment downtime, and reduced spending on health-related leave.

Planning Effective Acoustic Enclosures

Effective acoustic control begins with a detailed assessment of the noise environment. Operations and facility managers should measure sound pressure levels and identify dominant noise frequencies near the equipment. This initial acoustic assessment establishes a benchmark and helps define the required noise reduction target in decibels, tailored to both compliance standards and the specific characteristics of the machinery.

Defining a clear noise reduction target is essential. Managers should determine the current noise level and compare it to the acceptable threshold, often based on regulatory limits or internal safety goals. For example, if machinery produces 110 dB(A) and the aim is to reduce it below 85 dB(A), the enclosure must achieve a reduction of at least 25 dB. This target guides decisions on enclosure type, material selection, and thickness levels.

Modular and custom-built enclosures offer different advantages depending on operational priorities. Modular enclosures come prefabricated and are quick to install. They are cost-effective up front, flexible for future reconfiguration or expansion, and ideal for teams with limited construction resources.

Custom-built enclosures, on the other hand, excel in demanding environments where precise dimensions, fire resistance, or specific certifications are required. They deliver optimised performance tailored to site conditions, but typically involve higher initial costs and longer design lead times, though they tend to offer durability and a long service life.

Once the enclosure is in place, it is vital to validate its performance and track the business case. You should conduct noise measurements both before and after installation, ideally including frequency analysis to confirm attenuation targets are met. Monitoring metrics such as production errors, maintenance downtime, staff time off, and PPE usage provides tangible insight into operational improvements. Tracking return on investment over time reveals the value delivered by the acoustic solution.

Putting Engineering First for Quieter Operations

When thoughtful engineering drives the design of acoustic enclosures, industries gain more than reduced noise; they secure safer, more efficient, and more humane working environments. By applying sound science, like tailored composite panels, strategic absorption, robust seals, and intelligent enclosure design, DECIBEL transforms noisy machinery into production assets that no longer compromise worker well-being or operational clarity.

DECIBEL distinguishes itself through engineering-led, custom solutions that are both robust and practical. Our enclosures are designed to match specific machinery, environmental and regulatory needs. From concept to installation, we build acoustically certified systems that are ready for the factory floor and built to perform. Whether you need quiet enclosures for presses, pumps, generators or HVAC systems, we deliver solutions that protect workers and drive productivity.

If you're ready to create a quieter, safer environment with performance-driven engineering, get in touch today. We offer acoustic modelling, tailored enclosure design, and retrofit assessments to help you make effective, sustainable noise control part of your operations.